Honda

Honda Motor Europe Logistics focuses on reusable packaging

"Less waste and fewer lorries on the road”

Liesbeth Vande Velde, environmental coordinator

|

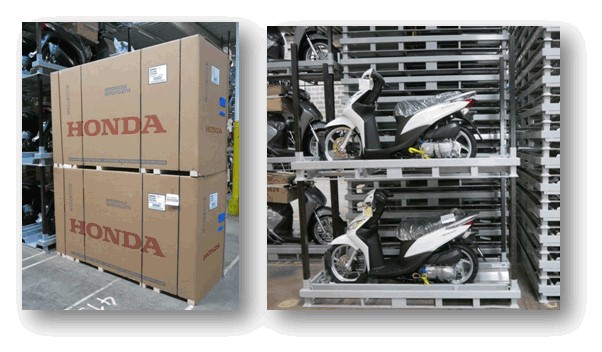

Honda Motor Europe Logistics began using reusable packaging over ten years ago. “In the meantime, we transport almost all our products in metal crates, which is not only cheaper but also sustainable.”

Honda Motor Europe Logistics is a subsidiary of the Japanese company Honda Motor, which produces cars, motorbikes and power equipment. All the company’s European transport of finished goods and product components is coordinated from its main storage depot in Ghent. “That naturally involves lots of packaging materials,” explains Liesbeth Vande Velde, the company’s environmental coordinator. “However, by replacing wood, plastic, cardboard and polystyrene with reusable metal crates, we have managed to dramatically reduce our waste flow.” Massive waste flow Ten years ago, Honda Motor began to focus on sustainable packaging materials. “It was quite incredible just how much waste packaging was circulating between Honda’s factories and logistical centres,” Vande Velde remembers. “We used wooden pallets, plastic shrink-wrap and cardboard boxes, and they all ended up in the bin afterwards. We now use a foldable metal crate to limit our waste. These crates can be reused almost eternally. The crates are used for journeys across Europe, as well as transport to and from Japan, Asia and the United States.”

Made to measure Honda Motor soon decided to develop various metal crates, in all shapes and sizes. Vande Velde: “These were originally designed together with our hauliers and suppliers, and that is how we still do it. For product components particularly, it is important that the crates are made to measure. For example, car windows used to be packed in a cardboard box with plenty of foam as protection for the fragile glass. These windows are now packed in a specially-designed metal crate. No other packaging is required: those receiving the window have no waste, other than a narrow protective strip on the edge of the window.” Sustainable stacking One advantage of metal crates is that they stack well. “We can fill our lorries better, while also properly protecting our products. Not only is a full container much safer, as goods are prevented from moving around during transport, it also reduces the number of lorries on the road. We can transport the same quantities of products and components with fewer journeys, and therefore reduce CO2 emissions. Even with the return journeys required to bring back the crates, there is still a greater benefit. The metal crates pay for themselves: our goods transport is much more efficient and we buy far less other packaging materials.” Ambitious intentions “One of Honda Motor’s global objectives is to recycle all the company’s waste and to send nothing to landfill,” confirms Vande Velde. “Our employees already have a strong recycling instinct. Any cardboard boxes that we receive are immediately sent to the packaging department for reuse. If the material is damaged, we shred the cardboard and use it as a filling. We will soon be switching from double-corrugated cardboard to single face corrugated cardboard, which is a thinner material. We are always looking for ways to improve.” |

Honda Motor Europe Logistics

Sectors Mobility ›