De Brabandere

De Brabandere supplies concrete granulate for premium use

“Green concrete is just as strong and much more sustainable”

Pieter De Brabandere, co-owner

|

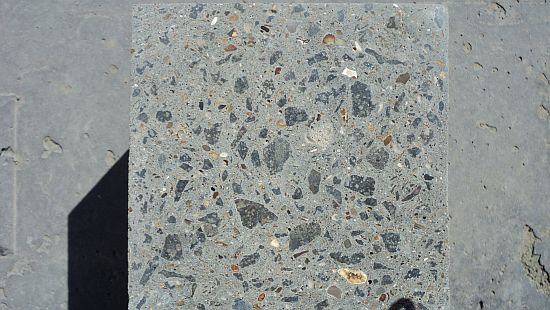

In recent years, the Road construction company De Brabandere has increasingly focused on recycling. The mountain of concrete collected by workers during road construction projects is broken down and turned into high-quality concrete granulate. “This means we require fewer natural granulates for our pouring concrete.”

As a road construction company, De Brabandere collects considerable amounts of concrete rubble. “In connection with the circular economy, we investigated how to create value with such rubble,” explains co-owner Pieter De Brabandere. “Initially, we only used concrete rubble as road foundations. Meanwhile, we use a specialised crushing procedure to transform the rubble into premium concrete granulate. This is then used to make pourable concrete in our concrete plant. In the past, we produced our pourable concrete entirely with natural granulates: crushed limestone or porphyry grit from quarries in Tournai or Lessines. That was hardly sustainable: we were obliged to extract raw materials and CO2 was released during transportation. We are now able to replace up to 50 per cent of the natural granulates with premium concrete granulate. This results in ‘green concrete’: just as strong but far more sustainable.” Other qualities Even though premium concrete granulate is equivalent to natural granulates in many ways, the two materials are not identical, admits Pieter De Brabandere. “Some of the properties of concrete granulate differ from natural granulates. This poses no problem, as long as you have sufficient knowledge to handle the differences. In our concrete plant, we develop the types of concrete that allow for the specific properties of concrete granulate, and are therefore sure to have no surprises. The end result is just as strong and reliable as traditional concrete.”

Strict legislation The Flemish government enforces strict regulations on the production of green concrete. De Brabandere was the first company in Belgium to receive a certificate. “It is only now that we have one, that we are finally able to launch our concrete granulate on the market for premium applications,” says Pieter De Brabandere. “The strict rules are required to prevent cowboys entering the market with an inferior product. Recycling is not always taken seriously by everybody. However, in our company, sustainability plays a very important role. We have been working hard for four generations and intend to remain the leader in our domain. Sustainable innovations fit beautifully with our strategic vision.” New range Eco-Beton The demand for our new range of Eco-Beton – the commercial name for our green concrete – is already greater than the supply. It can therefore be called a success. Pieter De Brabandere: “Meanwhile, we are using our green concrete for roads, cycle paths, walls, flooring, etc. Veurne and De Panne are some of the proud owners of roads made entirely from premium concrete granulate, and Diksmuide boasts a cycle path made of green concrete. As a founding member of Groen Beton Vert vzw, I try to influence the legislation and encourage other companies to use our product. In the longer term, we also wish our French company to benefit from our knowledge. We are working hard to build a sustainable building sector.” |

De Brabandere

Sectors Construction ›