EMMA safety shoe

A shoe with a passport

100% circular safety shoe

After a period of intensive research, EMMA Safety Footwear launched its next generation of safety shoes: safer, more comfortable AND 100% circular. Fully equipped with a material passport and a service device to provide carefree logistics for returns.

|

|

|

Safety first, with sustainability following closely in it's footsteps

To be specific, this means avoiding the use of (primary) raw materials, avoiding energy use and CO2 emissions, reclaiming raw materials and using them in new products. Suppliers need to meet certain conditions like for example material use. That’s how the use of PVC stopped.

What does circular manufacturing mean to EMMA?

Full circular manufacturing at EMMA Safety Footwear means, among other things:

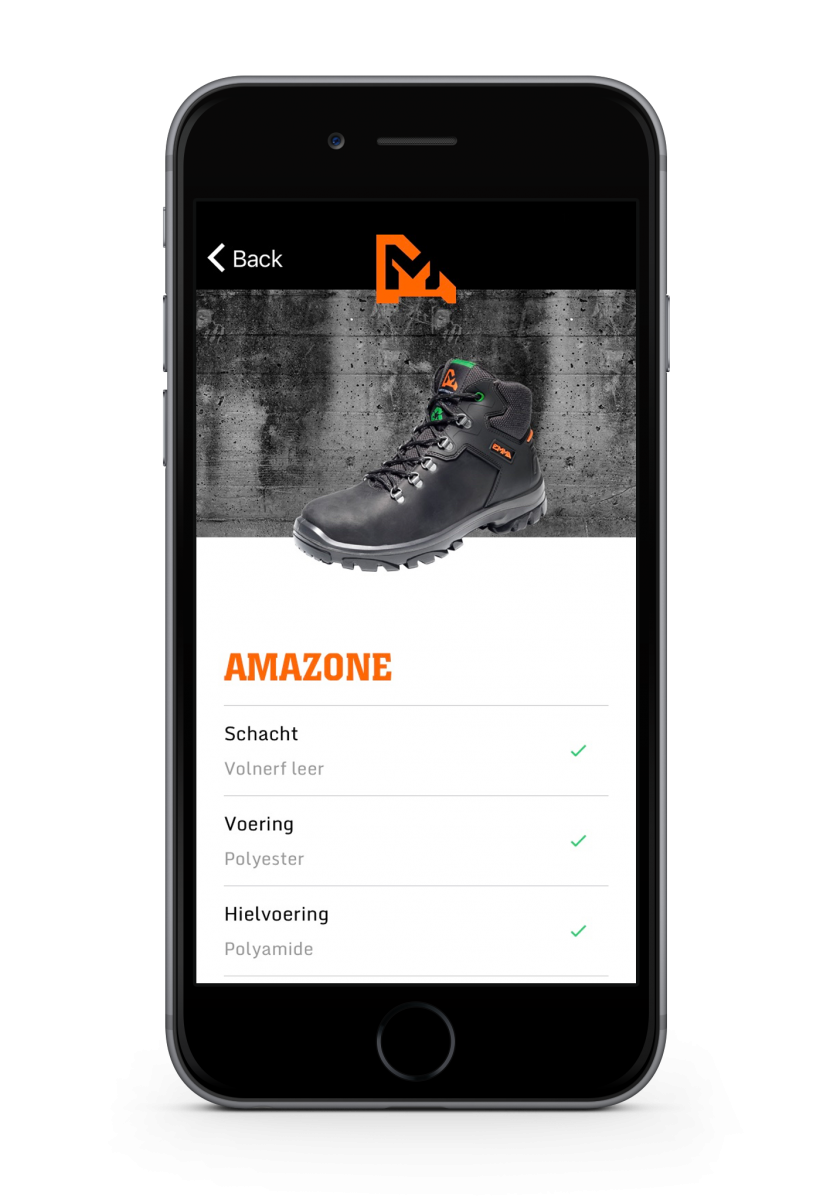

• Every circular shoe has its own material passport.

• The materials in the shoe have been selected for their long useful life.

• All raw materials are reused. • A future application is known for every material.

• All shoes are individually identified in order to be able to trace them throughout the chain.

Together with its chain partners, EMMA Safety Footwear makes sure that the shoes are returned, that the raw materials are registered in a materials database and that the raw materials are reused for new products. Also collected shoes from other manufacturers are usefully recycled up to 80%. For example, the leather is ground and used in armrests for cars. Starting in 2019, recycled material will be added to the shoes. At present, the inner sole is made of 70% recycled material and the laces are made of used PET bottles, which are recycled after use. The number of different materials used in the shaft of the shoe was reduced to 5 parts.

Safety as a service

EMMA Safety Footwear's ambition goes a step further with the full service package it aims to provide. This involves all aspects related to choosing, trying on, wearing, caring and returning a shoe. This leads to safety as a service: where the customer no longer pays for ownership, but simply to use the products. The raw materials remain the property of EMMA Safety Footwear, before, during and after use. By linking sustainable clean raw materials to an efficient logistics system for returns, raw materials can retain their value, the use of primary raw materials is significantly reduced and existing raw materials can be reused as a raw material.

Focus on people

Ever since its foundation in 1931 EMMA Safety Footwear has been generating a positive social impact by opting for diversity and inclusiveness in its organization. EMMA Safety Footwear currently employs over 100 people with difficulties accessing the labour market. EMMA Safety Footwear offers its staff the opportunity to use their talents and develop themselves. The focus does not stop at employment conditions in the Netherlands. EMMA Safety Footwear also ensures that its suppliers and chain partners provide a safe environment for the people that work there every day on EMMA shoes.

|

|

|

Next steps

EMMA Safety Footwear aims to set an example in energy positive manufacturing and a sustainable economy. There is still lots left to achieve. In the end the company wishes to work only with sustainable energy and to make sure that water is returned clean, in all production sites in the chain. Using innovation, EMMA Safety Footwear aims to ensure that production can continue in Europe, and where possible be repatriated, allowing the creation of new jobs.

EMMA Safety Footwear

Sectors Textile and Fashion ›