Low-migration inks

With low-migration inks, Agfa has created a breakthrough in inkjet for food packaging

"Gaining accreditation across the world creates a bit of a buzz among the dozens of people that have worked on this new development."

Marc Graindourze, Business Development Manager

Agfa-Gevaert has been an intrinsic part of the world of graphic design and printing technology since time immemorial. The traditional printing techniques such as offset have been replaced in the various markets by inkjet for many decades. Inkjet is much more flexible. The printing process is controlled directly from a digital file and that enables production changes to occur more rapidly. The process is more economical in terms of energy and material compared to offset and flexography. In addition, digital printing technology can be integrated within a production environment on location. Transport to and from printing locations is therefore unnecessary.

"If we take rolled-out banners for promoting new products in shops or large panels along the roadside as an example, nowadays they are largely printed digitally using inkjet technology", explains Marc Graindourze. The past few decades have been dominated by the transition to inkjet in the advertising poster sector. As a result of its scale, Agfa is constantly on the lookout for new markets and areas of application for its technology.

"An enormous market which offers the opportunity for a great deal of conversion from traditional printing to inkjet, is that of packaging. If you want to gain a foot in the door, however, you must come up with a solution for food packaging."

Around 50% of product packaging is food-related. The norms that correspond to food safety are extremely strict. The printing inks must not migrate through the packaging and contaminate the food.

In order to come up with a solution, the innovation challenges were initially divided up into achievable steps. Alongside the basic concept of the composition of the inks, for example, (which had to be so-called low-migration inks), adjusting the ink to the printing process, the speed of hardening, and the specific functional requirements of the packaging, also had to be considered.

"So, it's more than just ink. It is an all-encompassing approach that must accommodate the risk of contamination."

In the first few years, until around 2009, the basis of the formulae for the low-migration inkjet inks was determined and patented. Since then, in collaboration with the producers of all-in printing machines, complete solutions have been developed for drinks packaging, butter dishes, yoghurt packaging, etc.

The big difficulty with inkjet is that the ink must be roughly as liquid as water in order to pass through the tiny openings, which are sometimes no wider than a hair's breadth, on the sprayer head. On the other hand, you must ensure that the ink components do not migrate through the packaging; this is easy for molecules with a high molecular weight but this creates high viscosity inks. The core of the innovation is that Agfa has created a type of ink formulation that is easy to spray and simultaneously, during hardening (under UV light) is characterised by a high degree of polymerisation and a very low level of migration.

"With respect to analogue solutions, this innovation offers a number of sustainability advantages."

A great advantage is that labels no longer need to be applied to packaging. The packaging can take the printing directly. The exact number of packs required can therefore be printed before being filled with the food product. Rapid changeovers are also possible; "If you need to print 2,225 packs with an Easter chick, exclusively for a short promotion for a chain store, you can do so without additional product losses." Packaging can also be printed at the relevant location and not in a printing facility miles away. The entire chain is thus quicker and shorter, uses less energy and creates lower levels of material waste. Also, no volatile organic compounds are released. The risk of food loss in the chain is also reduced.

In contrast to what the name 'low-migration ink' may suggest, it's not just about the ink. Agfa is also working with printer manufacturers on developing a system solution whereby the ink is set according to the packaging-specific requirements during the course of the project. The printer manufacturer sells an integrated system, including Agfa's low-migration inks, to the packaging producer. Sometimes, they are the food producers themselves.

"Winning the Essenscia Innovation Award 2014 was an important event and accreditation for our innovation", says Marc Graindourze. "There was a very positive response internally too and the efforts of all of the employees that had been involved were very much appreciated."

"Innovation is a team process, as is the process of maintaining it, with constant monitoring and adjustment of the aims where necessary. A motivated and multidisciplinary research and development team can be engaged in multiple projects at the same time; this allows researchers to work on projects that have reached different stages. "Gaining accreditation across the world creates a bit of a buzz among the dozens of people that have worked on this new development." This project is a great example of how Agfa is capitalising on technology and market trends within which digital printing can offer a better solution than analogue printing. This type of project requires a durable, long-term commitment. This innovation would not have been possible without the support of the IWT (Agency for Innovation through Science and Technology)."

OVAM SIS Toolkit

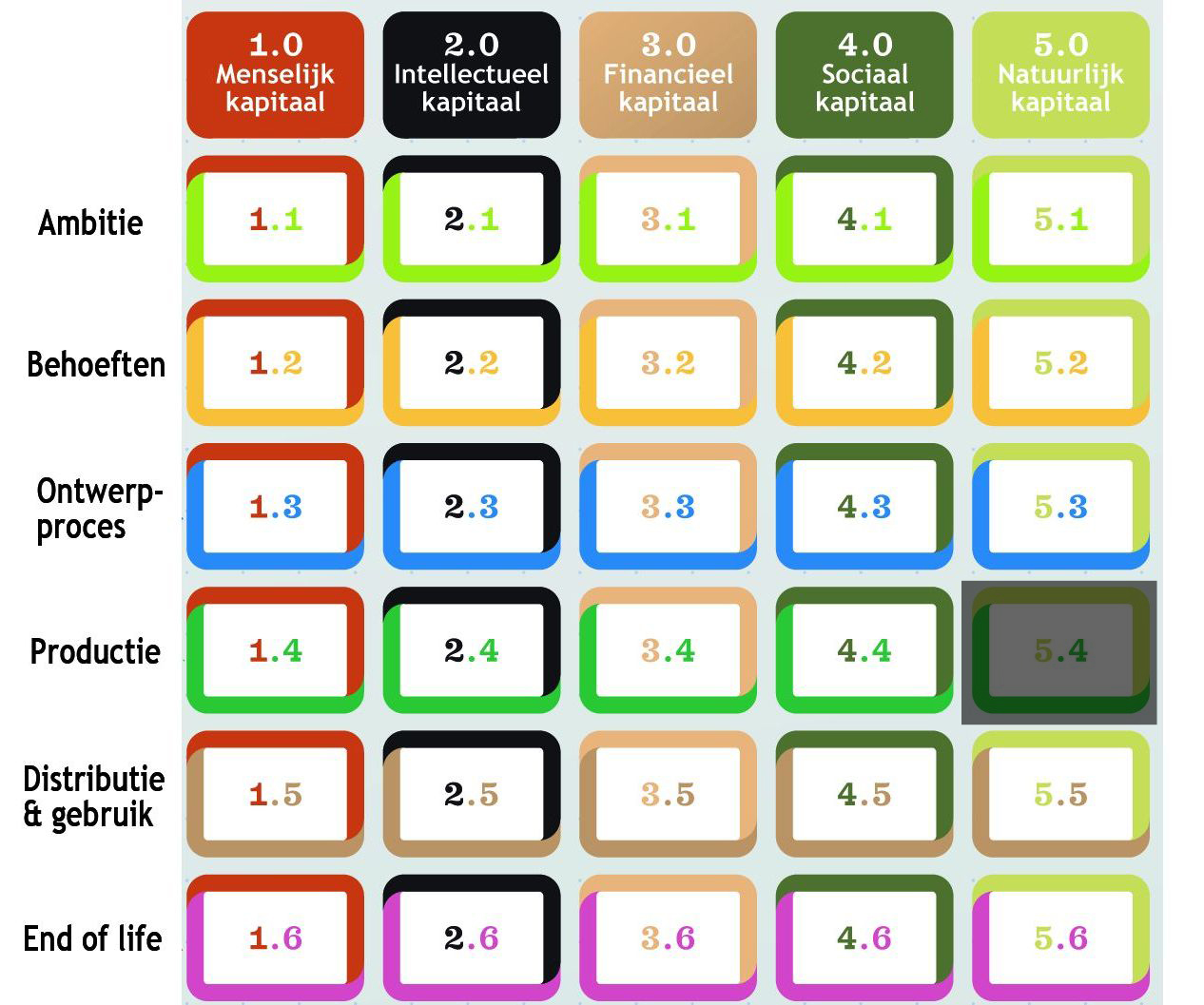

De grijs gearceerde delen van de OVAM SIS Toolkit-matrix duiden aan op welke snijpunten de case goed scoort.

More information on the OVAM SIS Toolkit

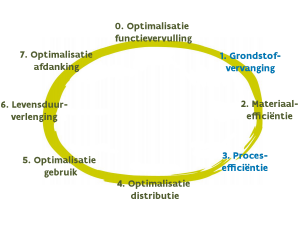

Applied ecodesign strategies

Agfa Graphics

Sectors Chemicals ›